Teflon Lip Seal / PTFE Lip Seal

Description of Teflon Lip Seal

Teflon lip seals, also known as PTFE lip seals, are specialized sealing components engineered with polytetrafluoroethylene (PTFE), commonly known as Teflon. This high-performance material is renowned for its exceptional chemical resistance, low friction properties, and ability to withstand extreme temperatures, making it an ideal choice for demanding sealing applications.

PRESSURE UP TO 10 / 15 / 250 BAR

Function and Working Principle of Teflon Lip Seal

Teflon lip seal / PTFE radial lip seals usually have a thin cross-section to deal with PTFE's stiffness, especially in cases where the shaft isn't perfectly aligned. This thin design also helps control expansion and keeps the seal in contact with the shaft. In most designs, the seal's body is clamped between two metal cases to maintain pressure. Keeping the design simple helps control costs. However, in cases where there's no lubrication and wear is expected to be high, a thicker design might be used. In some designs, the seal might end up with a wider contact area than intended, but this happens because of the pressure needed to keep the seal working correctly on the shaft.

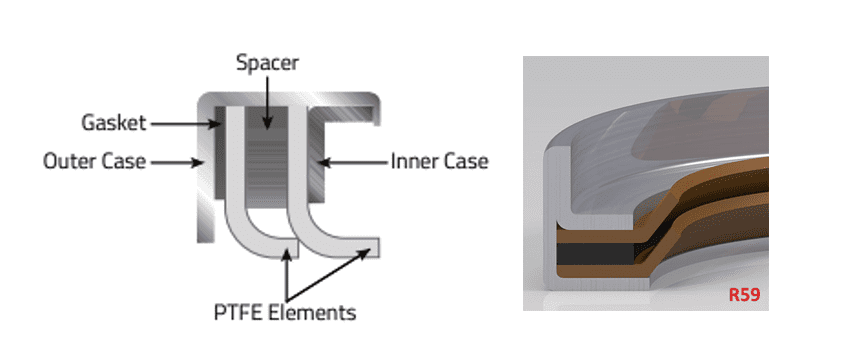

The following are the design features of the Teflon Lip Seal

Outer Case -Houses all components of seal -Press-fit into the bore to prevent seal rotation

Inner Case -Compress internal components -Locates bend point of element

Gasket -Helps prevent internal leakage -Takes up tolerances in assembly

Spacer -Locates bend point of element -Spaces multiple elements apart for ideal sealing

PTFE element(s) -Mechanically formed to a diameter smaller than shaft -Takes advantage of hoop stress of PTFE

This video from the Garlock group explains the working principle and functionality of Teflon Lip Seal which is also know as PTFE Lip Seal.

Advantages of Teflon Lip Seal

Superior Chemical Resistance: Teflon lip seals exhibit outstanding resistance to a wide range of chemicals, acids, and solvents, ensuring reliable sealing performance in corrosive environments.

Low Friction: The inherent low-friction properties of Teflon reduce wear and friction between the seal and the shaft, resulting in smoother operation and extended seal lifespan.

High Temperature Stability: Teflon lip seals can withstand extreme temperatures, ranging from cryogenic conditions to elevated temperatures, without compromising their sealing integrity.

Excellent Wear Resistance: Teflon's exceptional wear resistance ensures long-lasting performance, even in high-speed rotating applications where abrasion and wear are common.

Minimal Maintenance: Thanks to their durable and self-lubricating properties, Teflon lip seals require minimal maintenance, reducing downtime and maintenance costs for industrial operations.

Applications of Teflon Lip Seal

Teflon lip seals find applications across various industries and machinery, including:

Chemical Processing: Pumps, mixers, and reactors handling corrosive fluids.

Food and Beverage: Processing equipment requiring hygienic sealing solutions.

Industrial Machinery: Pumps, compressors, gearboxes, and rotating equipment.

Automotive: Engines, transmissions, and axle assemblies.

Aerospace: Aircraft engines, hydraulic systems, and landing gear.

Oil and Gas: Offshore drilling rigs, pipelines, and processing facilities.

Teflon Lip Seal Application Industries

-

Food Processing Industry

-

Pumps, Motors and Gearboxes

-

Medical and Pharma Industry

-

Automotive Industry

-

Chemical Processing, Oil and Gas Industry

-

Machine Tools Industry

Product Features of Teflon Lip Seal

High-Pressure sealing application

Pressure up to 10 Bar / 15 Bar / 250 Bar

Shaft speed up to 10 - 40 m/s

Materials Composite PTFE + Elastomer + SS

Temperature range -40°C to 220°C

Various profiles are available for different applications