Description of VR Lip Seal

At CV Technik, we are proud to offer high-quality lip seals manufactured by VR Dichtungen GmbH, a trusted name in the industry known for its precision engineering and durable materials. The lip seals are designed to provide reliable sealing for a wide range of applications, ensuring optimal performance and longevity.

With a focus on quality and innovation, VR lip seals are manufactured to meet the stringent demands of various industries, including automotive, aerospace, manufacturing, and more. VR’s extensive product portfolio includes a variety of lip seal designs, materials, and sizes to suit diverse needs and requirements.

Whether you're looking for standard lip seals or custom solutions tailored to your specific applications, CV Technik has you covered. Explore our comprehensive range of VR lip seals and experience their reliability and efficiency.

Trust CV Technik for all your lip seal needs and discover why we are the preferred choice for professionals across industries. Contact us today to learn more about our lip seal offerings or to place an order.

PRESSURE UP TO 10/15/150 BAR

Function and Working Principle of VR Lip Seal

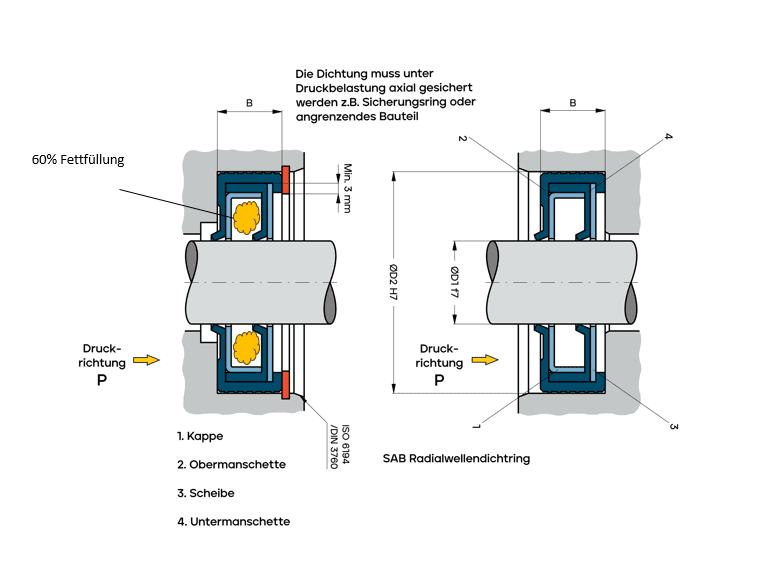

The operational concept of this springless VR radial shaft seal hinges on the utilization of rubber-elastic sleeve bodies, properly tensioned over supporting elements made from stainless steel or other metals. The sealing lip, which is inclined and interfaces with the sleeve body, adjusts its orientation—either inward or outward—depending on the installation configuration and the directional pressure of the sealed medium.

The sealing action is facilitated by the radial and tangential tension exerted on the sleeve body. This tension imparts a spring-like characteristic to the sleeve, ensuring optimal contact between the sealing lip and the rotating shaft. Consequently, the seal effectively mitigates shear stresses induced by rotational motion and adeptly absorbs vibrations and deviations in concentricity, enhancing its operational stability.

Furthermore, the seal's construction minimizes the risk of the sealing lip partially lifting during shaft rotation, thereby mitigating any potential pumping effects. This meticulous design approach ensures the seal's reliability and longevity in demanding applications.

Advantages of VR Lip Seal

High-pressure applications (10 Bar/15 Bar/ 150 Bar)

Highly suitable for compact space application

No damage to the shaft

Very little scoring due to the springless feature

Very little power loss due to less friction on the shaft surface

Suitable in food, medical and critical sealing application

Applications of VR Lip Seal

All applications where standard oil seal fails to withstand high pressure and also for compact spaces where standard oil seals are difficult to install.

General mechanical engineering (e.g. spindle seals)

Electrical engineering (e.g. motors, rotary encoders)

Medical technology (e.g. very small seals for pumps and instruments)

Pump construction / fan construction (e.g. submersible pumps, centrifugal pumps, axial fans)

Compressor construction (e.g. screw compressors)

Automotive (e.g. climate compressors)

Food machines (e.g. kneading machines)

Agitator and blender and liquidizer technology (e.g. bowl cutter, milk powder machines)

Household machines (e.g. blender, lye pumps, washing machines)

Shipbuilding (e.g. ship shafts)

Gear construction (e.g. high-speed transmission gearing, spur gears)

General vehicle building (e.g. water pump seal, gearbox seal)

Rotary union (e.g. pneumatic controls)

VR Lip Seal Application Industries

-

Automotive Industry

-

Steel and Heavy Engineering

-

Pumps, Motors and Gearboxes

-

Food and Pharma Industry

Product Features of VR Lip Seal

High-Pressure sealing application

Pressure up to 10 Bar / 15 Bar / 150 Bar

Shaft speed up to Vmax 40 m/s

Materials NBR / FKM / HNBR / EPDM / Silicone or VMQ / Custom

Temperature range -40°C to 220°C

Various profiles are available for different applications

Custom materials and dimensions can be supplied as per your demand